Manufacturing technologies often hide fascinating stories behind their seemingly straightforward processes. Twin screw extrusion represents one such marvel of engineering, a process that quietly powers numerous products we use every day. Beyond its industrial applications, this technology harbors surprising complexities and innovations that few outside the manufacturing world understand.

1. More Than Just Plastics

While most people associate extrusion with plastic production, twin screw extruders work magic across multiple industries. Food processing relies heavily on this technology to create everything from breakfast cereals to pet food. In the pharmaceutical sector, twin screw extruders play a crucial role in producing controlled-release medications and nutraceutical supplements.

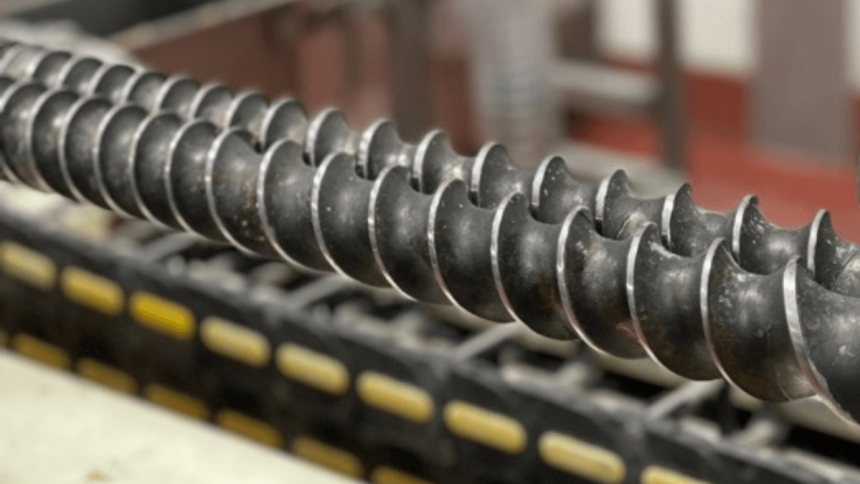

The versatility stems from the extruder’s unique ability to mix, heat, and shape materials under precise conditions. Unlike single screw systems, twin screw extruders offer superior mixing capabilities, making them ideal for complex material formulations that require thorough integration of multiple components.

2. A Molecular Transformation Machine

What looks like a simple mechanical process is actually a sophisticated molecular engineering technique. As materials pass through the intermeshing screws, they undergo dramatic transformations: the combination of mechanical shear, temperature, and pressure can fundamentally alter material properties at the molecular level.

This means twin screw extruders don’t just shape materials, they can actually modify their chemical structure. Manufacturers use this capability to enhance material performance, introducing new characteristics like improved strength, flexibility, or thermal resistance that weren’t present in the original raw materials.

3. Environmental Innovation Powerhouse

Sustainability represents a critical advantage of twin screw extrusion. These systems excel at processing recycled materials, allowing manufacturers to incorporate higher percentages of post-consumer waste into new products. The precise control and superior mixing capabilities mean recycled materials can be transformed into high-quality end products more efficiently than with traditional manufacturing methods.

Some advanced twin screw extruders can now process complex waste streams that were previously considered unrecyclable.

4. Precision Engineering at Microscopic Scales

The engineering behind twin screw extruders is mind-bogglingly precise since screw designs can be customized with microscopic variations that dramatically influence material processing. Manufacturers can also modify screw flight depths, add specialized mixing elements, and create complex geometries that optimize material flow and transformation.

Moreover, modern twin screw extruders incorporate sensors that can detect variations as small as micrometers, allowing for real-time adjustments during production. This level of precision ensures consistent product quality across massive production runs.

5. A Technology Driving Material Innovation

Twin screw extrusion is pushing the boundaries of material science. Researchers use these systems to develop entirely new material combinations: from advanced aerospace materials to cutting-edge medical devices, twin screw technology enables engineers to experiment with material formulations that were once considered theoretical.

The process has become a critical tool for developing materials with specific performance characteristics.

So, as manufacturing continues to evolve, twin screw extrusion stands at the intersection of engineering, chemistry, and innovation, because what appears to be a straightforward industrial process is actually a sophisticated technology reshaping how we create and understand materials.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.

![[Hand-Picked] 6 Best Proxy Browsers for Anonymous Experience](https://www.readability.com/wp-content/uploads/2025/04/Hand-Picked-6-Best-Proxy-Browsers-for-Anonymous-Experience-150x150.png)