Packaging plays an important role in just about every business. You may be packaging your products to keep them fresh or simply to prevent them from getting damaged during the shipping process.

That said, you may already have invested in a heat sealing machine to make this process simpler and more cost-effective. If that’s the case, it’s important to maintain your sealing machine to ensure optimal performance.

Heat Sealing Machines Defined

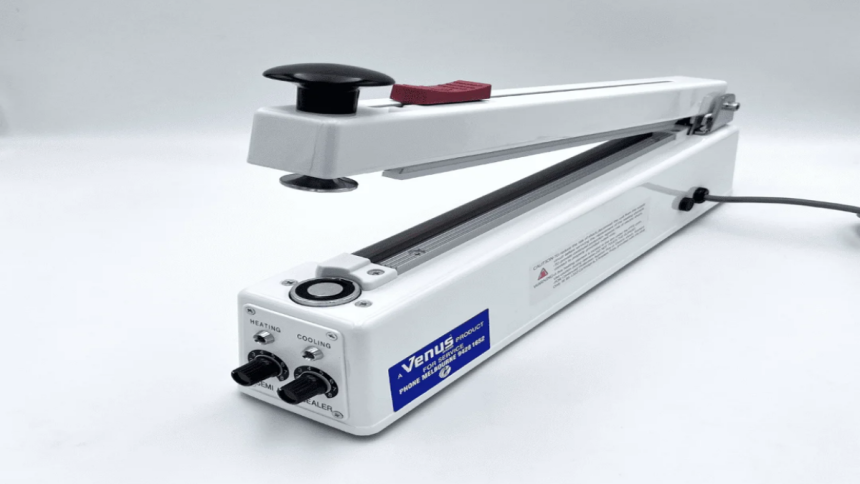

As the name suggests, a heat sealing machine uses heat to melt two pieces of specialized film together to create a strong bond. For the most part, heat sealing is used to protect delicate products such as electronic components and pharmaceuticals during transit. Alternatively, food items can also be sealed in this way to maintain freshness and improve shelf-life.

Benefits of Heat Sealing

There are several benefits to opting for his packaging solution. The most significant ones are listed below.

- Doesn’t require additional adhesion: During the heat sealing process, two pieces of plastic or film are melted together. Since this doesn’t require any additional adhesive, there’s also a significant cost-saving factor.

- Creates a superior, tamper-proof seal: A strong, tamper-proof seal ensures that small components don’t fall out of packaging during transit. It’s also impossible for bags to be opened and resealed after items have been removed.

- Ensures products are secure in a protective material: Shipping and transit processes often mean that every package is handled many times. Without the correct packaging, it’s easier for items to get damaged or lost. The strong seal created by heat sealing ensures that this doesn’t happen.

Maintenance is Easier than You Think

As with any other machine in your business, your heat sealing machine will require routine maintenance to ensure that it continues functioning correctly. You also want to avoid those annoying breakdowns that not only cause downtime in your business but also eat into your profits. We’ve listed a few steps that will help you keep your heat sealer in tip-top shape.

1. Preventative Maintenance

When it comes to machinery in your business, you should always invest in preventative maintenance. This is significantly better than only dealing with it once it’s already broken and causing downtime. The best way to do this is to create a maintenance schedule that won’t hamper the usual business flow.

Some tasks may be routine enough for you to do yourself. However, if you’re not entirely comfortable with this, enlist the services of a certified service technician. Always opt for someone who has been approved by the manufacturer to service that specific model.

Typically, the technician will perform the following routine maintenance tasks:

- Check the machine thoroughly

- Replace components that have worn out

- Ensure that significant spare parts are kept in stock

- Lubricate necessary components

2. Create a Maintenance Checklist

If you’re going to be doing routine maintenance yourself, it’s essential to check the manufacturer’s guide for the frequency of these tasks. Use this information to create a checklist of tasks that must be done daily, weekly, monthly, and even quarterly. This will help you stay up to date with the maintenance tasks.

It’s always a good idea to involve the person who operates the machine in the maintenance process. Since they’re always working with it, they may be able to identify changes in the usual productivity of the unit.

3. Liase with the Manufacturer

Wherever possible, always collaborate with the manufacturer or retail agent to ensure that you get a speedy response to any queries. Ideally, you should check the availability of a customer service department before purchasing the heat sealer.

Being able to speak to a real person is the best way to get assistance with a simple issue that can be handled remotely. This will avoid having to spend additional money on costly call-out fees. Addressing the issue yourself also ensures that your packaging department is less likely to have downtime while you wait for a technician to be available.

4. Invest in a Few Additional Spare Parts

One very simple way to avoid having to wait for a technician, or a courier to deliver a specific spare part is to have your own backup stock. Check with the manufacturer for a list of spare parts. In some instances, manufacturers also list them according to how likely they are to wear out.

Of course, this is only a guideline as frequency of use will determine how often you need to replace certain parts. Over time you’ll be able to identify which parts wear out a lot and which parts you’ve never had to replace. It’s a good idea to keep one or two additional parts of the items that wear out the most.

Final Thoughts

Heat sealing is an effective way to ensure that your packages arrive safely at their destination. Adding a heat-sealing machine to your packaging process is the most cost-effective way to secure packages. Use the tips we’ve shared to maintain your heat-sealing machine so that it can continue sealing the way it should.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.