Air hose quick connect fittings are indispensable tools in various industries, offering a seamless way to join air hoses to equipment and tools. Understanding the different types of air hose quick connect fittings and their benefits can significantly enhance operational efficiency, safety, and convenience.

What Are Air Hose Quick Connect Fittings?

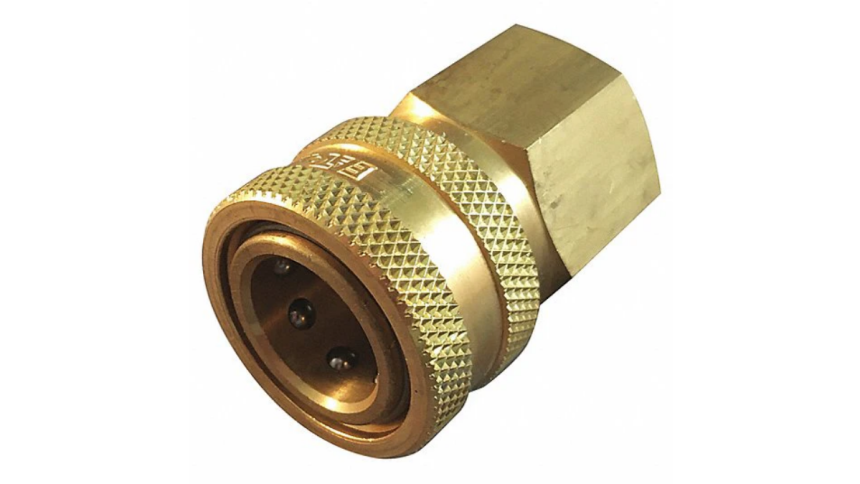

Air hose quick connect fittings are coupling devices that allow for the rapid connection and disconnection of air hoses without the need for tools. They are commonly used in pneumatic systems where compressed air is required to power tools and machinery. These fittings are designed to create an airtight seal that prevents leaks and ensures optimal performance.

Types of Air Hose Quick Connect Fittings

1. Industrial Interchange Fittings

- Type D: Known for their durable construction and high flow rate, making them ideal for heavy-duty industrial applications.

- Type M: Commonly used in automotive and general industrial settings due to their reliability and widespread availability.

2. Automotive Interchange Fittings

- Type C: Often found in automotive repair shops and garages, these fittings are easy to connect and disconnect, enhancing workflow efficiency.

- Type L: Designed for high-flow applications, they are perfect for tasks requiring a substantial amount of air pressure.

3. ARO Interchange Fittings

- Known for their robust design and versatility, ARO fittings are suitable for a wide range of industrial applications, providing a secure and leak-proof connection.

Benefits of Using Air Hose Quick Connect Fittings

- Increased Efficiency Quick connect fittings allow for rapid changes between different air tools and equipment, minimizing downtime and enhancing productivity. Workers can switch tools in seconds, which is especially beneficial in high-paced environments.

- Enhanced Safety The secure connection provided by quick connect fittings reduces the risk of air leaks, which can lead to accidents and equipment damage. Additionally, the ease of connection and disconnection minimizes the potential for injuries caused by struggling with traditional threaded fittings.

- Convenience and Ease of Use These fittings are designed for ease of use, enabling even those with minimal technical skills to connect and disconnect air hoses effortlessly. This simplicity translates to less training time for new employees and a more straightforward workflow.

- Versatility Air hose quick connect fittings are available in various styles and sizes to suit different applications. Whether you’re working in an industrial setting, a garage, or on a construction site, there is a fitting designed to meet your specific needs.

- Durability Made from high-quality materials such as brass, stainless steel, and hardened steel, these fittings are built to withstand harsh conditions and heavy use. Their durability ensures a long service life, providing excellent value for money.

How to Choose the Right Air Hose Quick Connect Fitting

When selecting air hose quick connect fittings, consider the following factors:

- Application Requirements Determine the specific needs of your application, including the required air pressure and flow rate, to choose a fitting that can handle the job efficiently.

- Material Compatibility Ensure that the fitting material is compatible with the air hose and the environment in which it will be used. For instance, stainless steel fittings are ideal for corrosive environments, while brass fittings are suitable for general use.

- Size and Compatibility Select fittings that match the size of your air hoses and tools. Using mismatched sizes can lead to leaks and inefficient performance.

- Brand and Quality Opt for reputable brands known for their quality and reliability. Investing in high-quality fittings can prevent frequent replacements and ensure a secure connection.

Conclusion

Air hose quick connect fittings are essential components in any pneumatic system, offering numerous benefits such as increased efficiency, enhanced safety, and ease of use. By understanding the different types and choosing the right fittings for your needs, you can optimize your operations and ensure a smooth, reliable workflow. Whether in industrial applications, automotive settings, or construction sites, these fittings provide a practical and efficient solution for connecting air hoses to tools and equipment.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.