Stainless steel door frames are crucial in the construction industry, known for their durability, aesthetic versatility, and resistance to environmental factors. Continuous technological advancements have significantly enhanced their design and functionality, catering to both safety and design needs of contemporary architecture. This article explores the latest innovations in stainless steel door frame technology, highlighting how these developments are shaping the future of building constructions.

Enhanced Corrosion Resistance

Innovation in corrosion resistance is central to the development of stainless steel door frames. The introduction of new alloys has been a game-changer in enhancing their durability. These alloys are specially designed to resist the corrosive effects of harsh environments such as coastal areas or industrial sites with high exposure to chemicals. By increasing the chromium, nickel, and molybdenum content, these frames offer superior protection against rust and degradation.

Advanced coating technologies have complemented these metallurgical advancements. Techniques such as electro-coating and powder coating apply protective layers that shield the frames from environmental elements while enhancing their aesthetic appeal. These coatings are available in a range of colors and finishes, allowing for greater design flexibility in architectural projects.

The benefits of these innovations extend beyond increased durability. They significantly reduce the need for maintenance and replacement, which can lower the long-term costs of building operations and minimize environmental impact. By extending the lifespan of stainless steel door frames, manufacturers contribute to more sustainable construction practices, reducing the demand for raw materials and the production of waste.

Fire Resistance and Safety

Advancements in fire safety technology have greatly improved the performance of stainless steel door frames in fire situations. These frames can now be equipped with materials that are resistant to high temperatures, slowing the spread of fire and providing critical time for evacuation. This enhancement is especially important in high-risk environments such as commercial buildings, hospitals, and schools.

Stringent testing and certification processes ensure that these fire-resistant door frames meet all necessary safety standards. The rigorous testing guarantees that the frames will perform under extreme conditions, providing peace of mind to both builders and occupants. This commitment to safety is reflected in the growing demand for certified fire-resistant construction materials.

The integration of fire safety features into stainless steel door frames allows architects to design safer buildings without compromising on style or functionality. This is increasingly important as building codes become stricter and safety becomes a paramount concern in architectural design.

Thermal and Acoustic Insulation

Recent innovations in stainless steel door frames have focused on improving their thermal and acoustic insulation capabilities. The incorporation of thermal breaks has been crucial in enhancing the energy efficiency of these frames. These breaks, often made from materials with low thermal conductivity, help to prevent heat transfer, keeping interiors more comfortable and reducing energy costs.

Acoustic insulation has also been significantly improved through advanced sealing technologies. These innovations help to minimize sound transmission, making stainless steel door frames an ideal choice for buildings in noisy environments or where sound insulation is a priority. Enhanced seals not only improve privacy but also contribute to the overall comfort of building occupants.

The combination of thermal and acoustic insulation benefits not only enhances the usability of buildings but also contributes to sustainability. By improving energy efficiency and reducing noise pollution, these frames support broader environmental and social objectives, aligning with global trends towards more sustainable and livable buildings.

Integration with Modern Technology

The integration of technology into stainless steel door frames is transforming their functionality. Equipped with smart technology, these frames can now monitor access and environmental conditions, integrating seamlessly with building management systems. This technological integration enhances building security and operational efficiency, making stainless steel frames an integral part of modern smart buildings.

Compatibility with advanced security systems has also been a focus of recent innovations. Stainless steel frames designed to accommodate modern locking mechanisms and control systems offer enhanced security, ensuring that buildings are equipped to meet the challenges of today’s security demands. This is crucial in areas requiring high levels of security, such as government buildings and commercial complexes.

The adaptability of stainless steel door frames to automated features further enhances their appeal. Features that facilitate automatic opening and closing not only improve accessibility but also ensure compliance with disability access regulations, making these frames suitable for a wide variety of applications and essential for inclusive design.

Selecting a Stainless Steel Door Frame Supplier

Choosing the right supplier for stainless steel door frames is essential for ensuring quality and reliability in your construction projects. A reputable supplier provides not only high-quality materials but also expertise in the latest technological innovations. When selecting a supplier, consider their range of products and their ability to offer customized solutions that meet specific project requirements.

It’s crucial to assess the supplier’s industry reputation and the quality of their customer service. A supplier that supports their products with strong customer service, technical support, and the ability to supply a wide range of options can significantly enhance the success of a project. Factors such as delivery times, customization capabilities, and after-sales support should also play a part in the decision-making process.

For professionals seeking top-quality stainless steel door frames that align with the latest trends in construction and technology, USA Fire Door is an excellent resource. With a broad selection of products and a commitment to high standards, they offer valuable solutions for contemporary building needs.

Aesthetic Innovations

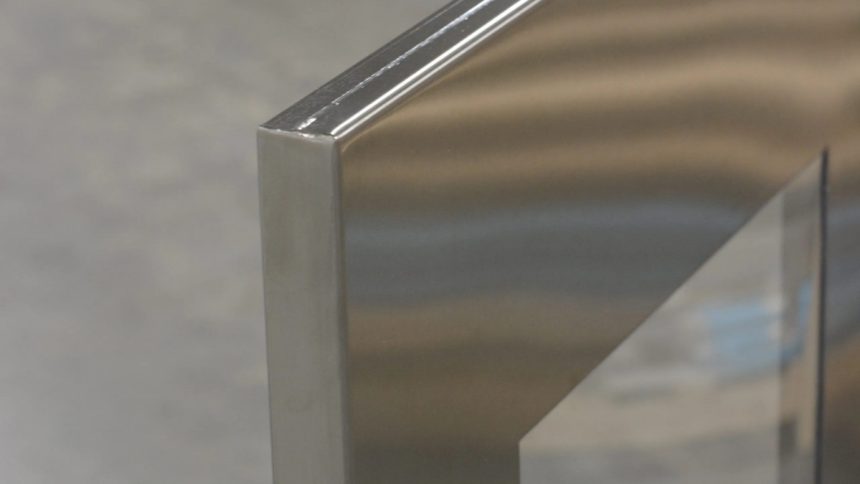

Technological advancements have expanded the aesthetic options available in stainless steel door frames. Modern fabrication techniques allow for greater customization, enabling architects to tailor frames to specific design visions. This flexibility is essential for incorporating stainless steel frames into various architectural styles, from ultra-modern to traditional.

The development of new finishes and textures provides designers with additional tools to integrate these frames seamlessly into their projects. Whether the goal is to complement a building’s exterior façade or to create a visually striking entryway, the latest innovations in stainless steel finishes meet a wide range of aesthetic requirements.

The role of stainless steel door frames in contemporary architecture has evolved to meet aesthetic, functional, and regulatory demands. Their enhanced design versatility and improved performance characteristics make them a key component in a broad range of construction projects, embodying the fusion of durability, safety, and style.

Advanced Manufacturing Techniques

The manufacturing processes for stainless steel door frames have undergone significant advancements, contributing further to the evolution of this crucial construction component. The implementation of precision engineering and automation in the manufacturing process has not only increased the production efficiency but also enhanced the quality and consistency of the final products. These technological enhancements facilitate the production of frames with complex shapes and sizes that were previously difficult to achieve, allowing for greater architectural freedom.

Laser cutting and CNC machining are now commonly used in the manufacturing of stainless steel door frames. These methods offer unmatched precision, which is essential for ensuring that the frames fit perfectly within the designated spaces, minimizing gaps and potential weaknesses. The precision also extends to the aesthetic aspects of the frames, allowing for intricate designs and detailing that can be replicated consistently across multiple units.

Moreover, the integration of digital technologies and Industry 4.0 practices into the manufacturing processes has improved the traceability and customization of door frames. Manufacturers can now offer bespoke solutions more efficiently, catering to specific client requirements such as enhanced security features or unique insulation properties. This shift not only meets the increasing demand for customized building materials but also aligns with sustainable manufacturing practices by reducing waste and optimizing resource use.

Final Thoughts

The innovations in stainless steel door frame technology have significantly reshaped their role in modern construction. With enhancements in every aspect of their design and functionality, these frames meet the evolving demands of the industry, providing solutions that are durable, safe, and aesthetically pleasing. As technology continues to advance, stainless steel door frames are poised to play an increasingly vital role in the future of architecture, setting new standards in construction and design.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.