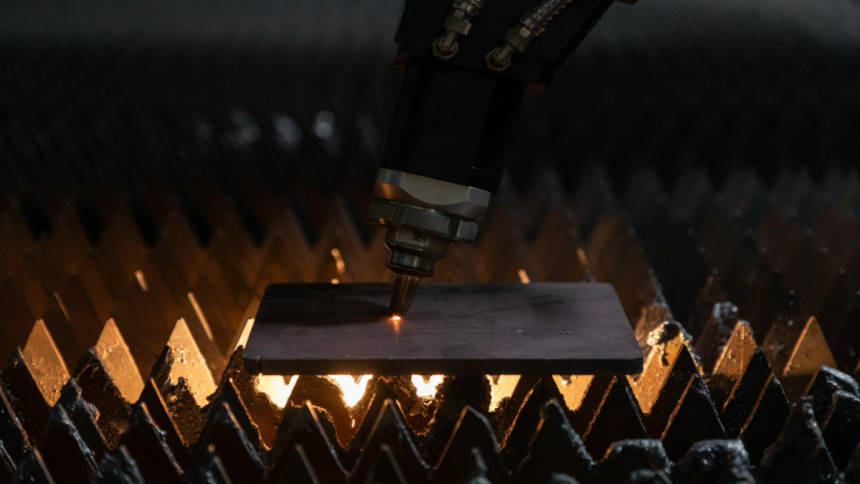

Smart manufacturing is revolutionizing industries worldwide by combining advanced technologies with streamlined processes to maximize efficiency and quality. Among the critical innovations shaping this transformation are fiber laser machines, known for their precision and adaptability. ACCURL fiber laser cutters are particularly renowned for their ability to deliver exceptional performance in cutting applications, contributing to enhanced productivity and cost-effectiveness. These machines play a pivotal role in optimizing manufacturing workflows, reducing waste, and enabling intricate designs that meet today’s demanding industrial standards. Their integration into smart manufacturing environments is not just a trend but a necessity for staying competitive in an evolving market.

What Is a Fiber Laser Machine?

A fiber laser machine is a type of laser cutting and engraving equipment that uses optical fiber doped with rare-earth elements to generate a high-intensity laser beam. Unlike traditional laser technologies, fiber lasers are compact, energy-efficient, and highly versatile, making them ideal for diverse industrial applications. They stand out due to their superior beam quality, which allows for precise cuts, even on reflective materials like aluminum and brass. Fiber lasers are now a cornerstone of smart manufacturing due to their reliability and minimal maintenance requirements.

How Do Fiber Laser Machines Work?

Fiber laser machines operate through a sequence of well-coordinated processes:

- Light Generation: A laser diode generates light, which is then transmitted through fiber optics.

- Light Amplification: The light is amplified within a doped fiber core, where rare-earth elements, such as ytterbium, enhance its intensity.

- Beam Delivery: The high-energy laser beam is directed through a series of lenses and mirrors to focus on the material surface.

- Material Interaction: The concentrated beam melts, vaporizes, or burns the material, creating precise cuts or engravings.

This intricate process ensures unparalleled precision and efficiency, making fiber lasers indispensable in modern manufacturing.

Why Are Fiber Lasers Used in Smart Manufacturing?

Fiber lasers offer several advantages that align perfectly with the goals of smart manufacturing:

- Speed: Rapid cutting speeds boost production rates.

- Precision: Exceptional accuracy minimizes errors and material waste.

- Energy Efficiency: Lower power consumption compared to other laser types.

- Durability: Fiber lasers have a longer operational lifespan.

- Versatility: Capable of cutting various materials, including metals and non-metals.

What Are the Benefits of Fiber Laser Machines?

Fiber laser machines bring numerous benefits to the table, including:

- High Precision: Enables intricate designs and tight tolerances.

- Faster Cutting Speeds: Reduces production time significantly.

- Energy Efficiency: Consumes less energy, lowering operational costs.

- Minimal Maintenance: Robust components reduce downtime.

- Ability to Cut Reflective Materials: Handles challenging materials like aluminum and brass without performance degradation.

- Eco-Friendly Operation: Produces less waste and requires no consumables like gas.

How Do Fiber Laser Machines Compare to Other Laser Technologies?

Fiber Laser vs. CO2 Laser Machines

Pros of Fiber Lasers:

- Higher cutting speed for thin materials.

- Energy-efficient operation.

- Compact design and longer lifespan.

Cons of Fiber Lasers:

- Higher initial cost.

Pros of CO2 Lasers:

- Better for non-metal materials like wood and acrylic.

- Lower upfront cost.

Cons of CO2 Lasers:

- Higher maintenance requirements.

- Slower cutting speeds for metals.

Fiber Laser vs. Solid-State Laser Machines

Key Differences:

- Fiber lasers use flexible optical fibers, while solid-state lasers rely on crystal rods.

- Fiber lasers are more efficient and durable.

- Solid-state lasers are better suited for specific applications like welding.

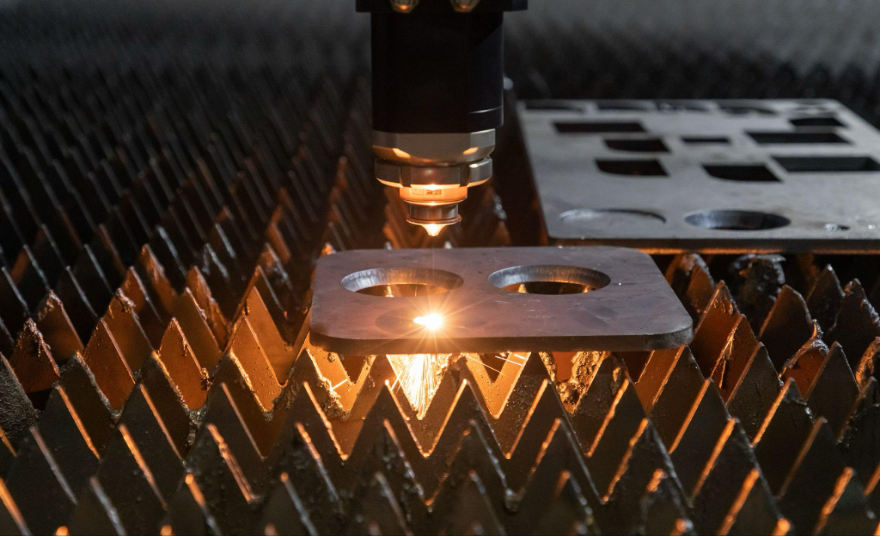

What Materials Can Fiber Lasers Cut?

Fiber lasers are versatile tools capable of cutting a wide range of materials.

Metals

- Mild Steel: Offers clean cuts with minimal slag.

- Stainless Steel: Ensures high precision for thin and thick sheets.

- Aluminum: Handles reflective surfaces effectively.

- Copper: Excels in cutting high-conductivity metals.

- Brass: Provides clean, precise results without burn marks.

Non-Metals

- Plastics: Cuts with precision, ideal for industrial and consumer applications.

- Composites: Handles multi-layered materials with ease.

How Do Fiber Lasers Maximize Efficiency?

Fiber lasers enhance efficiency through several features:

- Automation: Integrates seamlessly with robotic systems.

- Reduced Waste: Precision minimizes material loss.

- High-Speed Capabilities: Accelerates production cycles.

What Features Contribute to Efficiency?

- Advanced Software: Optimizes cutting paths and reduces errors.

- Automatic Focusing: Ensures consistent quality across different material thicknesses.

- Beam Quality Control: Delivers uniform results for intricate designs.

What Industries Benefit Most from Fiber Laser Machines?

Fiber laser machines serve various industries:

- Automotive: Cutting and welding complex parts.

- Aerospace: Producing high-precision components.

- Medical: Crafting surgical instruments with tight tolerances.

- Electronics: Cutting thin metal sheets for circuit boards.

What Factors Should Be Considered When Choosing a Fiber Laser Machine?

Key considerations include:

- Power: Determines cutting speed and material thickness capabilities.

- Size: Matches workspace requirements.

- Cost: Balances budget with feature requirements.

- Material Compatibility: Ensures suitability for intended applications.

What Are the Key Parameters for Fiber Laser Cutting?

Essential parameters include:

- Power Output: Influences cutting speed and material thickness.

- Cutting Speed: Impacts production efficiency.

- Kerf Width: Affects precision and material usage.

What Are Typical Cutting Tolerances?

- Mild Steel: ±0.1 mm for up to 6 mm thickness.

- Stainless Steel: ±0.2 mm for thicker sheets.

How Thick Can Fiber Lasers Cut?

- Mild Steel: Up to 25 mm (1 inch).

- Aluminum: Up to 15 mm (0.6 inches).

How to Use a Fiber Laser Machine Effectively?

Preparation Tips

- Ensure proper material setup.

- Clean lenses and surfaces.

- Calibrate the machine for optimal performance.

Safety Tips

- Wear proper eyewear to protect against laser radiation.

- Ensure adequate ventilation to remove fumes.

- Regularly inspect and maintain the machine.

Design Tips for Fiber Laser Cutting

- Account for kerf allowance in designs.

- Optimize for material thickness.

- Avoid unsupported areas to ensure structural integrity.

What Are Common Mistakes When Using Fiber Laser Machines?

- Incorrect parameter settings.

- Poor material handling.

- Neglecting routine maintenance.

- Overlooking safety protocols.

How Expensive Are Fiber Laser Machines?

What Is the Cost of Fiber Laser Machines?

- Industrial Models: $50,000 to $500,000.

- Entry-Level Models: $10,000 to $50,000.

Is Fiber Laser Cutting Expensive?

Operational costs include:

- Energy: Lower than CO2 lasers.

- Maintenance: Minimal due to durable components.

- Consumables: Rarely required, reducing ongoing costs.

Which Fiber Laser Machines Are the Best?

Key features to look for:

- Beam Quality: Ensures precision.

- Speed: Boosts productivity.

- Automation Features: Simplifies operations.

- Durability: Extends lifespan and reduces costs.

What Are Alternatives to Fiber Laser Cutting?

Alternatives include:

- Waterjet Cutting: Excels in cutting non-metals.

- Plasma Cutting: Cost-effective for thick metals.

- EDM (Electrical Discharge Machining): Ideal for intricate shapes.

Conclusion

Fiber laser machines are indispensable in smart manufacturing, offering unmatched precision, speed, and efficiency. Their versatility and cost-effectiveness empower industries to meet modern demands while minimizing waste. As the manufacturing landscape evolves, fiber lasers will remain at the forefront, driving productivity and innovation.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.