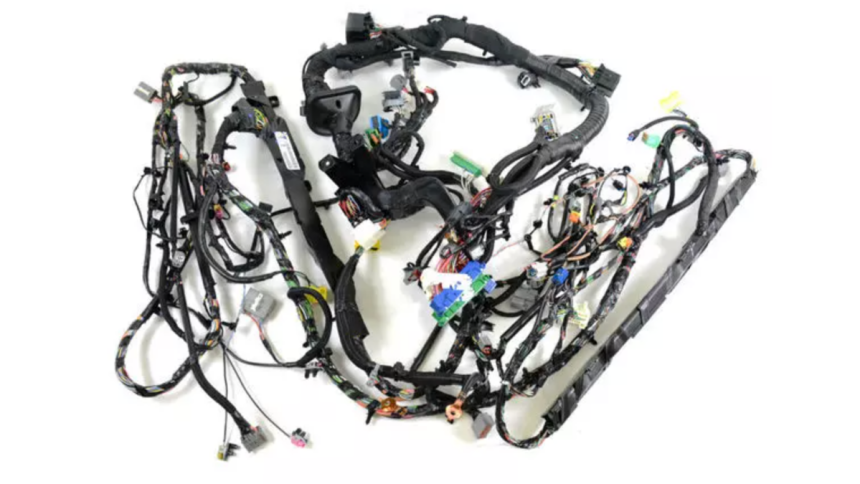

Wire harnesses are the unsung heroes behind many electronic systems, from your car’s dashboard to an aircraft’s intricate wiring. These assemblies of wires, connectors, and other components ensure efficient power and signal transmission.

Caption: wire harness of motor vehicle

Benefits of Wire Harness Assemblies:

- Streamlined Installation: Imagine trying to install each wire individually in a car. A wire harness consolidates this into a single unit, making installation faster and simpler.

- Enhanced Quality: Wires bundled within a harness are protected from damage, reducing the risk of electrical shorts and improving overall system reliability.

The Manufacturing Process:

The process begins with a design phase where engineers consider the equipment’s electrical and space requirements. A prototype is often created to ensure the design meets expectations.

Once the design is finalized, the manufacturing process involves several steps:

- Material Preparation: All necessary components, including wires, connectors, and insulation, are procured.

- Wire Cutting and Preparation: Wires are cut to precise lengths, stripped, and labeled.

- Crimping and Termination: Wires are connected to terminals and connectors using crimping tools, ensuring secure electrical connections.

- Assembly: Wires are bundled and secured within the harness according to the design.

- Testing: The finished harness undergoes rigorous testing to verify its functionality and safety.

Partnering with a Contract Manufacturer:

When working with a contract manufacturer, providing clear design specifications is key. Detailed drawings, a bill of materials, and testing requirements will facilitate smooth production.

Conclusion

Wire harness manufacturing is a complex but essential process that ensures the safe and efficient operation of countless electronic systems. From design to final testing, each step plays a crucial role in creating a high-quality product.

Remember, choosing the right manufacturing partner, like Cloom, with its diverse capabilities and commitment to quality, is essential for successful wire harness production.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.